Acrylic Fabrication: Key Benefits of Acrylic Sheets

If you are looking for a material that combines versatility, durability, and great aesthetics, acrylic fabrication is the solution. At Crown Plastics Inc., serving businesses in Jamestown, ND, we use our expertise to deliver products that fully harness the potential of acrylic fabrication for a wide range of applications. Acrylic sheets can be customized for everything from sleek retail displays to rugged industrial components. More businesses in Jamestown are turning to acrylic products because they offer outstanding clarity, resilience, and design freedom that outperform many traditional materials.

Understanding Acrylic Fabrication and Its Value

Acrylic fabrication involves turning sheets of acrylic into precise, purpose-built products. Acrylic is a type of plastic known for its strength, light weight, and glass-like transparency, but it also offers notable advantages over glass and other polymers. Acrylic sheets, sometimes called Plexiglas, can be machined, cut, routed, and bonded into nearly any shape or structure you require. At Crown Plastics Inc., we use the latest tools and technology to produce acrylic parts that are both visually appealing and engineered for performance.

One of the main advantages of acrylic fabrication is its adaptability to different needs. Acrylic sheets come in various thicknesses, colors, and finishes, so whether you need a protective shield, a display case, or a custom enclosure, there’s an acrylic solution available.

If you want to see the wide variety of options we offer, you can view our acrylic fabrication services.

Outstanding Optical Clarity

When it comes to transparency, acrylic sheets stand out. They offer up to 92% light transmission, which is higher than most alternatives, including standard glass. This makes acrylic a popular choice for any application where clarity is key—like retail displays, signage, museum cases, and windows.

Because acrylic products resist yellowing and hazing over time, you can count on them to stay clear and visually appealing for years. Optical clarity is especially important for industries that need attractive and durable presentation, such as healthcare, retail, and the nonprofit sector.

Superior Strength and Impact Resistance

Acrylic sheets are valued not only for their looks but also for being much stronger than glass. In fact, acrylic can be up to 17 times more impact-resistant than standard glass. This makes it a reliable choice for high-traffic environments such as manufacturing facilities, schools, and public spaces where safety is a priority.

In agriculture and automotive applications, acrylic pieces are used for both protection and durability. It’s common to see acrylic barriers in greenhouses or as automotive window replacements, thanks to their long-lasting strength and resistance to breakage.

UV Resistance for Outdoor Solutions

One of the standout features of acrylic sheets is their natural resistance to ultraviolet rays. Over time, exposure to sunlight can weaken or discolor many materials, but acrylic holds up remarkably well. This quality makes acrylic sheets an ideal choice for outdoor signage, canopies, skylights, and architectural features in environments subject to harsh sunlight.

Our team at Crown Plastics Inc. helps local businesses in Jamestown, ND, take advantage of this UV resistance for everything from advertising displays to functional covers for industrial equipment. Acrylic fabrication allows these products to last longer and require less maintenance compared to many alternatives.

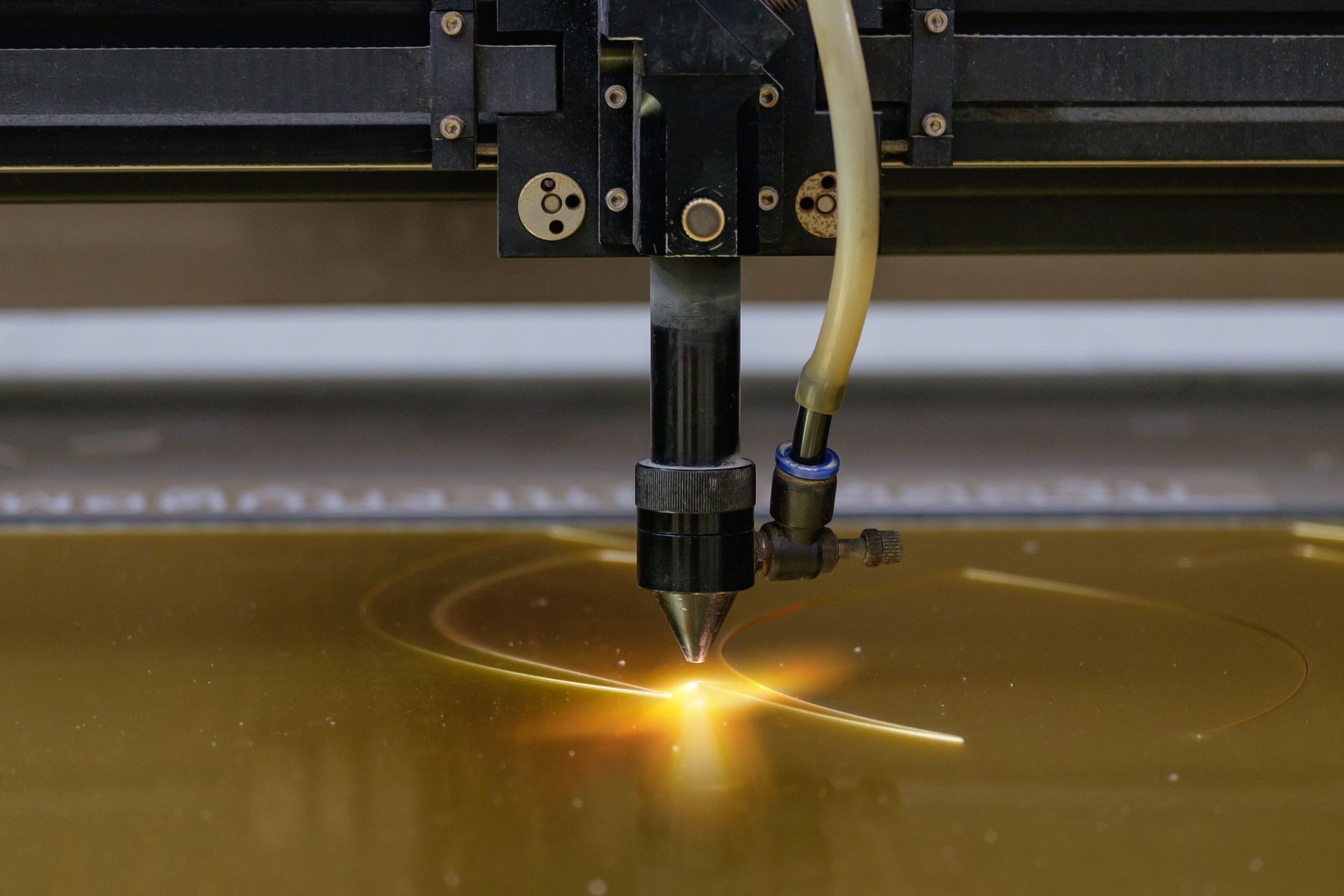

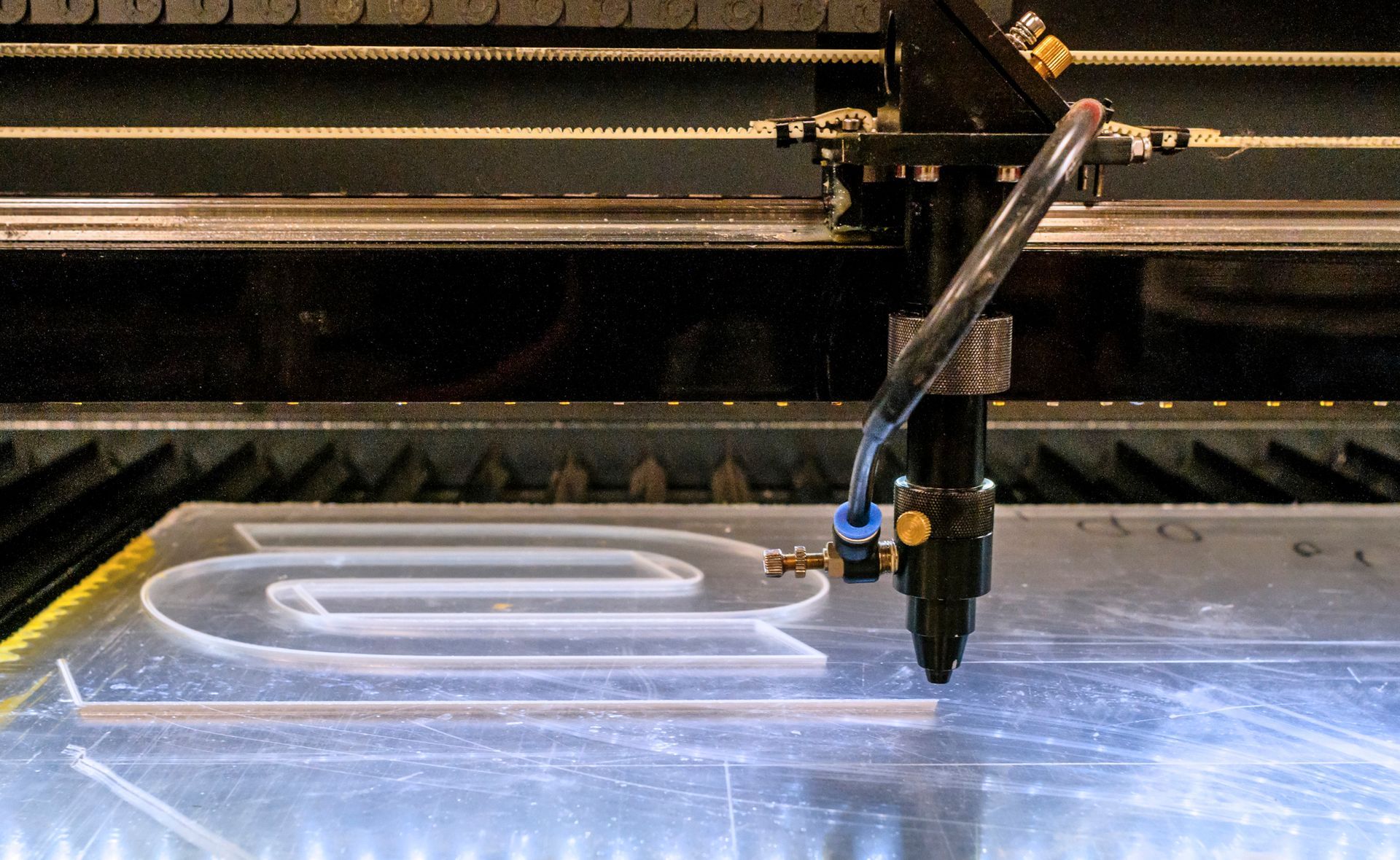

Easy Machining and Customization

Acrylic fabrication offers endless possibilities for customization. Acrylic sheets can be laser cut, bent, routed, drilled, and finished with a high level of precision. This means you can achieve both complex designs and tight tolerances. Unique shapes, custom sizes, logos, and engravings are all possible.

Businesses appreciate being able to personalize items like donation boxes, equipment covers, or branding signage, knowing that acrylic can adapt to almost any creative vision. The flexibility of acrylic fabrication also means that modifications and iterations can be made quickly, which is ideal for prototypes or evolving designs.

Longevity and Low Maintenance

The lifespan of acrylic products is another benefit not to be overlooked. Acrylic sheets resist weather, moisture, and corrosion, making them a cost-effective long-term choice. Cleaning is simple—mild soap and water keep surfaces spotless and streak-free, with no need for special treatments.

Lower maintenance costs and dependable performance make acrylic a preferred option in industries that require sanitation and safety, including healthcare and food service. Because acrylic products are shatter-resistant, they pose less risk in demanding environments, adding to their appeal.

Broad Industry Applications

Acrylic sheets are found everywhere, thanks to their versatility. At Crown Plastics Inc., we serve clients in sectors including:

- Healthcare: Protective barriers, equipment enclosures, and easy-to-clean surfaces.

- Retail: Point-of-purchase displays, shelving, signage, and product stands that require clarity and strength.

- Manufacturing: Machine guards and viewing panels that keep workers safe.

- Agriculture: Greenhouse panels and equipment covers exposed to the elements.

- Automotive: Custom windows, sunroofs, and panel replacements.

- Construction: Partitions, architectural features, and awnings that demand both looks and durability.

Acrylic sheets can even be used in creative arts, design, and exhibition installations, combining functionality with visual impact. If you want to see more about our expertise and variety of applications, check out our acrylic fabrication capabilities.

Why Partner With Crown Plastics Inc.?

As a provider serving the Jamestown, ND region, Crown Plastics Inc. brings decades of experience in design, customization, and production. We help our clients navigate material choices and fabrication methods, ensuring every project meets industry standards. Our team focuses on delivering both function and style, using high-quality acrylic sheets tailored to unique business needs.

Our dedication to quality, technical precision, and knowledgeable support means you can trust us to deliver the right solution the first time. From consultation and design to finished product and installation, we manage the full process to ensure top results for every client.

Ready to Begin Your Next Acrylic Project?

If you are exploring options for your upcoming project or need a material that offers outstanding durability and appearance, let’s talk. Our team at Crown Plastics Inc. provides acrylic fabrication solutions that serve the Jamestown, ND, area and beyond. We’re here to help you create lasting, high-performing products using the best acrylic sheets and fabrication techniques available.

Ready to experience the advantages of acrylic for your business?

Contact us today or call

(763) 557-6000 or

(800) 423-2769 to start your next project with Crown Plastics Inc. Our team looks forward to partnering with you.